When you open this article, it means that you are planning to start a poultry farming business, whether it is a laying hen or a broiler business. You need to pay attention to the things to be dealt with before, during and after the project. And have a certain basic understanding of local chicken farming knowledge and technology.

√ Planning new construction: Seeking best practices for building a chicken farm from scratch, including site selection, building type, internal layout, etc.

√ Optimization and upgrading: Hope to improve the productivity, animal welfare, disease control or cost-effectiveness of existing farms.

√ Seeking professional guidance: Looking for industry experts, design solutions or related equipment suppliers.

√ Understanding trends: Pay attention to cutting-edge design concepts such as sustainability, automation, and environmental control.

√ Cost-effectiveness considerations: Hope to understand the input-output ratio of different design solutions

This article is mainly to help novices or small-scale farmers in the farming industry to establish and start a poultry farm of a certain scale, increase customers’ farming income and market share, and help customers succeed!

1.How to choose the site of the chicken farm?

The ideal chicken farm site selection should take into account the following factors:

√ Water supply: Adequate and clean water is the basis of breeding.

√ Power supply: Modern breeding has a large demand for electricity, so ensure a stable and reliable power supply.

√ Transportation convenience: Convenient for the transportation of feed, chicks, medicines and products.

√ Distance from residential areas and water sources: Must comply with local environmental regulations to avoid pollution and nuisance.

√ Terrain and drainage: Choose an area with higher terrain and good drainage to avoid waterlogging and disease.

√ Natural wind direction: Natural ventilation but avoid wind outlets.

√ Land cost and scalability: Consider the possibility of future expansion

2.what is the best size for a chicken farm?

The “optimal size” is not a fixed number, but depends on your investment budget, market demand, labor availability, management capabilities, and local regulations.

Small family farms (hundreds to thousands):

Suitable for beginners, low investment risk, relatively simple management, can be used as a sideline or supply to the local market.

Medium-sized farms (5,000 – 30,000):

have certain economies of scale, and the degree of management and automation can be moderately improved. It is an ideal choice for many professional farmers, which can not only ensure the output, but also will not bring too much management pressure.

Large-scale commercial farms (more than 50,000):

pursue the maximum economies of scale, high automation and specialization. It requires strong capital, professional management team and stable market sales.

Recommendation: Using Retech farming chicken farming equipment, it is recommended to start with 10,000 chickens, accumulate experience, and gradually expand. In this way, you can experience the advantages of large-scale management and effectively control risks.

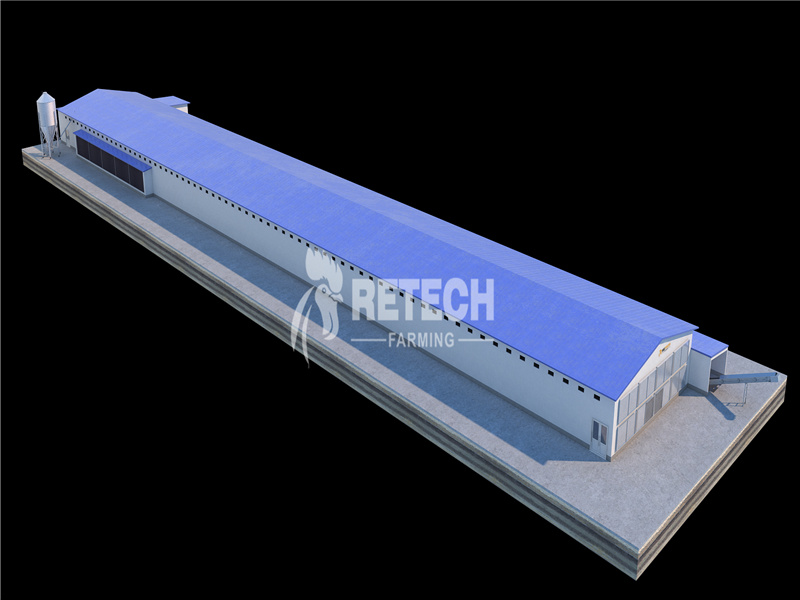

3.How to plan and design chicken houses?

The type of chicken house directly affects the breeding environment and management methods. The choice depends on your budget, climate conditions and breeding scale.

Open chicken house:

Low cost, using natural ventilation and light. Suitable for breeding in mild climates and small scales. But it is not well protected against extreme weather and is easily disturbed by the external environment.

Semi-open chicken house:

Some of the walls are adjustable, combining the advantages of open and closed. While providing a certain degree of protection, it can still take advantage of some natural conditions.

Closed chicken house (environmentally controlled chicken house):

Use advanced ventilation, cooling, heating and lighting systems to achieve precise environmental control. It is most conducive to the health of the chickens and improves production efficiency. It is particularly suitable for large-scale, high-density farming and extreme climate areas. The initial investment is high, but the long-term return is significant.

4.Which type of chicken cage is better for you?

4.1 Battery Cages for Laying Hens

Features: Usually multi-tier cages, each layer of the cage is designed with multiple cells, and the bottom has a slope to facilitate the rolling of eggs.

Advantages:

• Save floor space;

• Easy to manage, automated feeding, drinking water, egg collection and manure cleaning, mechanized operation improves feeding efficiency;

• Effectively control the spread of diseases;

Types:

• Automated H-type laying hen cage

• Automated A-type laying hen cage

• Simple A-type laying hen cage

Selection basis: production target, automation requirements, local regulations and market acceptance of animal welfare products.

4.2 Broiler Cages

Features: Compared with laying hen cages, broiler cages are usually more spacious, with plastic mesh at the bottom, easy to clean, and special waterers and feed trays.

Advantages:

• Increase stocking density,

• Facilitate mechanized feeding and water collection, reduce the cost of bedding and disease risks of ground farming, and improve feed conversion rate.

Type:

• Automated chain-type chicken cage

• Automated drawer-type broiler cage

• Automated ground feeding system

Choice basis: Suitable for large-scale, factory-based farming, with high requirements for environmental control.

4.3 Brooding Cages

Features: Designed for chicks aged 0-6 weeks, providing a constant temperature and well-ventilated environment. The cage bottom has a fine mesh to prevent damage to the chicks’ feet.

Advantages: It helps chicks grow healthily, reduces mortality, and facilitates brooding management, such as vaccination and feed conversion.

Summary: No matter which cage you choose, you should pay attention to the durability of its material, the ease of cleaning, the ventilation effect, and whether it can meet the growth and development needs of the chickens.

5.How to start a chicken farming business?

Retech farming is a leading poultry farming equipment production service provider. We provide A-Z solutions, leave the project to us and help you start your chicken farming business!

6.Poultry farm design for 10000 birds

Assumptions:

Farming type: laying hens (egg-laying cycle of about 72 weeks) or broilers (marketing cycle of about 40-50 days).

Cage type: 3-4 tiers laying hen cage/broiler battery cage.

Level: Automatic chicken raising system。

Including automatic feeding, drinking, ventilation, egg collection (laying hens)/manure cleaning.

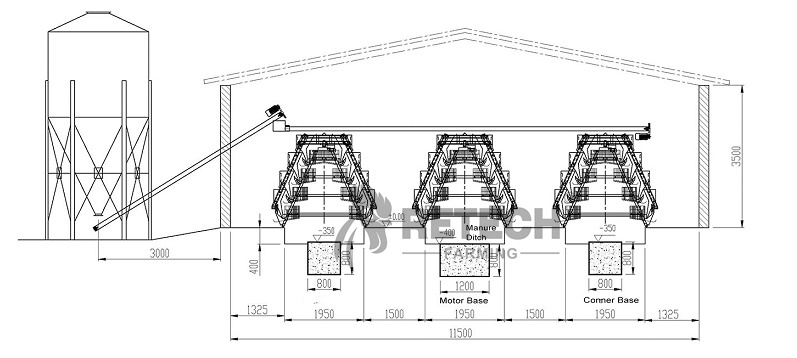

1. Number and size of chicken houses:

Laying hens: 10,000 layers,using A-type laying hen cages, each set of equipment can raise 160 chickens.

Broilers: 10,000 broilers, using battery cages or ground flat farming.

2. Functional Area Division:

Production area: Chicken house (core area).

Management area: office, staff lounge, locker room, disinfection room.

Storage area: feed storage, medicine and vaccine storage, material warehouse.

Product processing area: egg collection room/packaging area (laying hens), cold storage (broilers).

Manure treatment area: manure composting site or treatment facility.

Dead animal treatment area: harmless treatment facility.

3. Equipment configuration:

Feeding system: fully automatic feed line (chain or auger type).

Drinking water system: fully automatic nipple drinker.

Environmental control system:

fan (wet curtain fan cooling system), heater, ventilation window, environmental controller (intelligent change of temperature and humidity, CO2, ammonia).

Lighting system: LED dimming lamp.

Egg collection system (laying hens): automatic egg collection belt, egg collection machine.

Manure cleaning system: automatic manure cleaning belt.

Others: generator (backup power supply), high-pressure washing equipment, disinfection equipment, veterinary equipment.

4. Biosafety:

Strict entry and exit management: vehicle disinfection pool, personnel changing clothes disinfection.

Partition isolation: keep distance between different chicken houses.

Isolation observation area: independent area for new chickens or sick chickens.

5. Manure treatment:

Automatic manure cleaning belt is used to collect chicken manure at the end of the chicken house.

Resource use through composting, fermentation tank or biomass energy conversion is both environmentally friendly and can generate added value.

Important note: The above is only the design concept of a 10,000 chicken farm. The specific design needs to be based on your land area, local climate, budget and automation needs. Retech’s professional team will provide you with detailed engineering planning and drawing drawings.

Contact us for a project quote!

Post time: Jun-03-2025